Oblong hole

|

Need further information? |

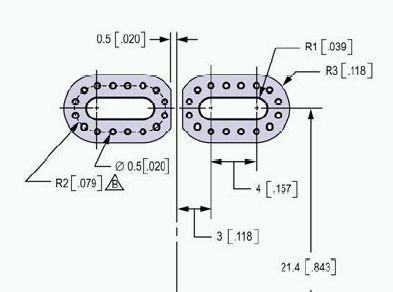

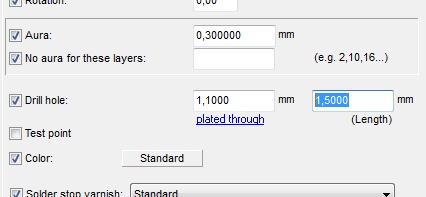

Display of an oblong hole in a data sheet

Oblong holes are displayed in datasheets that way for example:

Image 1: Two oblong holes

An oblong hole is a "Drillhole" brought to length. Others call it a slotted drill or a slotted hole. It is manufactured either by nibbling (an iterative number of drills in the dimensions of the desired slot) or by a milling tool. Such tools at least shall be 1 mm strong. In consequence the slot preferrably should be 1 mm wide. Smaller slots are difficult to create.

Nibbling or milling of an oblong hole?

You define to nibble a slot, which is a well accepted technique when "drilling" oblong holes. Nibbling means putting a multitude of drills in a row very close to each other. It might leave a small inner collar of annuli which would reduce the dimension of the slot. So please add a bit when defining the dimensions of the oblong hole.

Image: The principle of a nibbled slot. It is several drills side by side.

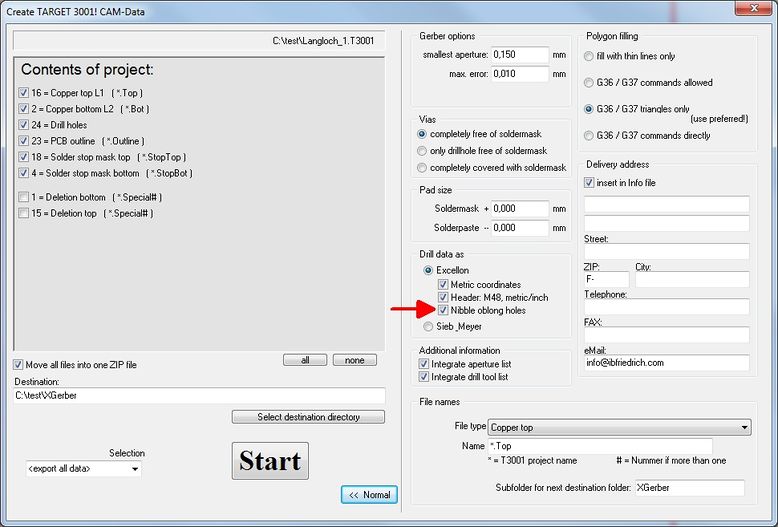

Go to the dialog "Create TARGET 3001! CAM-Data" and tick the box "Nibble oblong holes", see image. If you leave the box unticked, the mnufacturer might use a different technique to create the slot, e.g. milling, see explanation below.

Image: The option: Nibble oblong holes in the dialog "Create TARGET 3001! CAM-Data"

A pad with an oblong hole

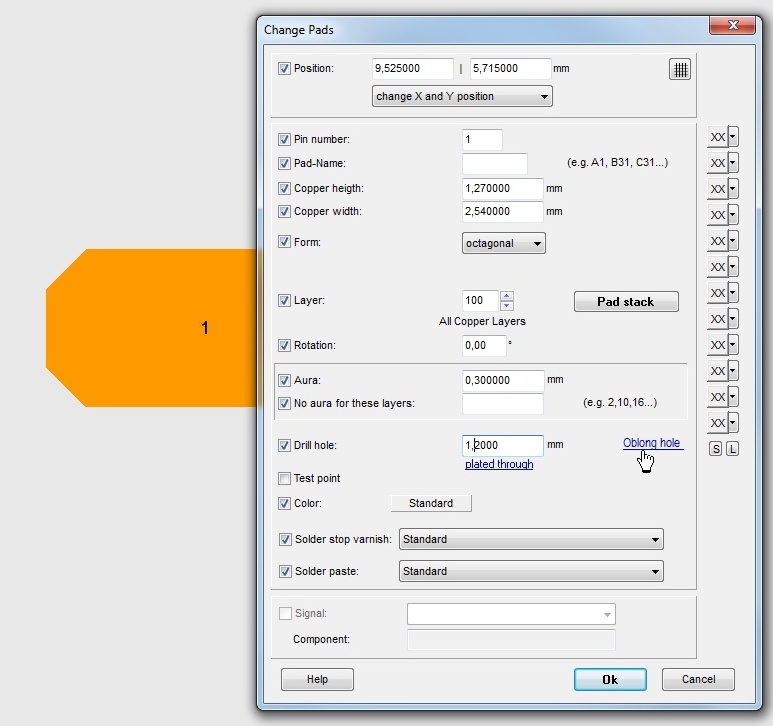

To give a pad an oblong hole please use the dialog Change Pads or - a priori - the dialog Pad Options.

Double click on a pad to open the Change Pads dialog. Close to the entry "Drill hole" you'll see the link Oblong hole.

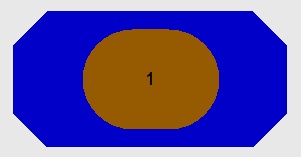

Image: The link: Oblong hole in dialog Change Pads...

Image: ...allows edition of a slotted hole in horizontal imagination.

Image: This pad has got an slot (oblong hole) of 1,5mm length and 1,1mm hight. Its height results from the width of the drill i.e. the diameter of the tool. If it is not at least 1 mm wide, the following message appears:

Image: A drill diameter less than 1 mm is too small for many PCB houses.

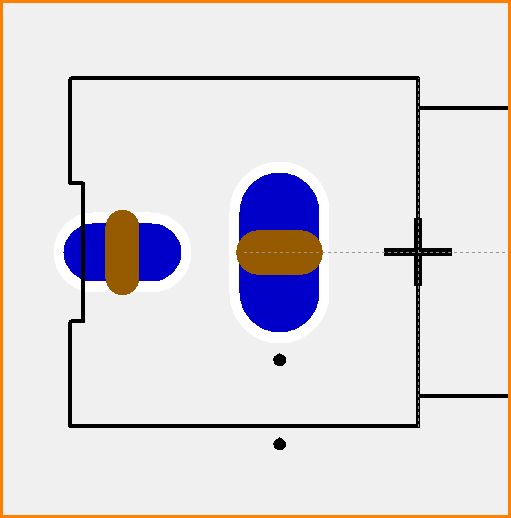

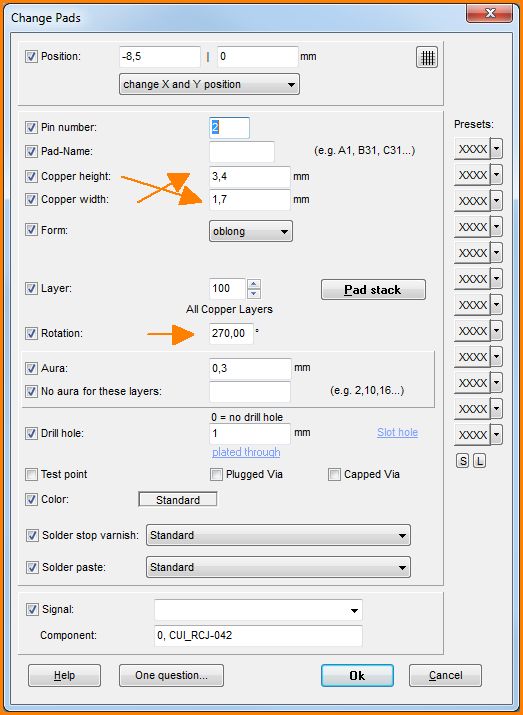

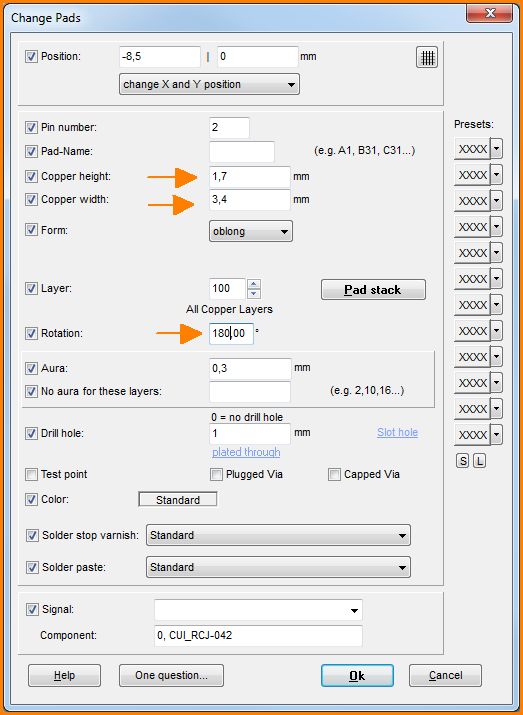

Orientation of the oblong hole is wrong

Image: Double-clicking the pad and defining the oblong hole might give the above image, but this is not what we desire. The holes (brown) are aligned incorrectly. Rotating the whole part by 90° at the beginning won't help either.

Image: Solution: Exchange the values in the fields for copper height and copper width. At the same time, change the orientation by 90° (270° becomes 180°).

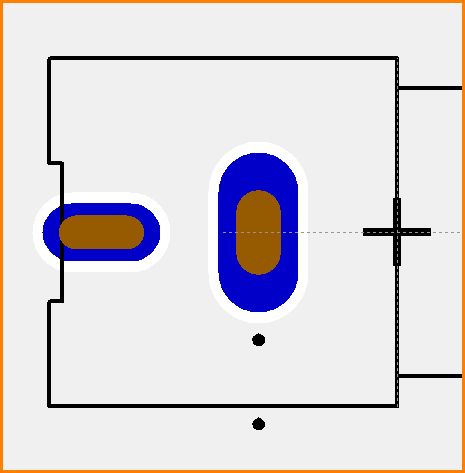

Image: Entering the avove mentioned values to the fields. Repeat the same procedure for other Pads.

Image: Now things are looking much better.

Alternative: Milling an oblong hole

If an oblong hole shall be surrounded by copper and plated through, please draw a pad showing the desired copper shape and create the oblong hole as a milling. The milling itself please draw as a line having the desired dimensions upon the milling layer (by default layer 25, Milling). Select the drawing tool from the tool bar and press M2 on the milling layer in the side bar in order to activate it. The width/length of the drawn line defines the dimensions of the milling.

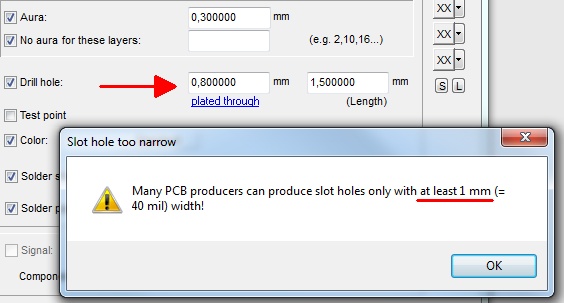

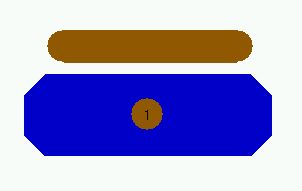

The following image shows the principle of creating a lengthened octagonal pad having a drill hole and having a milling command over it on layer 25 (brown). Change the pad form to "Oblong" in the pad dialog.

Image 2: An individually shaped THT pad with an additional milling command (above just to illustrate)

Now push the milling in position using M1H and superpose it to the drilling.

Image 3: A pad with an oblong hole. It is a milled slot superposed to the drilling.

Your PCB house will mill the oblong hole accordingly. Normally the rule applies: "As long as the copper around is bigger than the drilling (a so called rest ring remains), the figure gets plated through." This is not always the same with milling. Because it depends on the question when the milling will be done: Before the plating or afterwards. Regarding the "plating through" in this case please contact your PCB house how they handle such. Maybe you should add a little explanatory text in respect to the milling here.

.