RoHS

From July 1st 2006 all electronic products sold in the EC must comlply with the Restriction of Hazardous Substances Directive 2002/95/EC of the european parliament and the council on the restriction of the use of certain hazardous substances in electrical and electronic equipment (RoHS-Directive). The aim of this directive is to ban certain hazardous substances from electronic equipment toallow the recycling of those equipment. Electronic development which is compliant to thesse demands needs CAD tools, which support the developer from the beginning, because by far there is more behind it than just leadfree soldering. A system of integrated documentation and information is requested, which offers interfaces to other systems of corporate planning and control as well as opportunities for extension. The developer needs a comprehensive Component Management System (CMS) which guarantees RoHS compliance down to component basis. Analyzing/documentation opportunities which focus on the complete project to assure staying beneath the critical values based on the Bill of Material are a major need too.

The TARGET 3001! Component Management System (CMS) offers a multitude of functions which support efficient RoHS compliant design:

Based on library specific needs:

- Parallel administration of RoHS compliant and not compliantlibraries (in the TARGET 3001! library browser)

- RoHS-compliance as searching criterum (in the TARGET 3001! professional search)

- Supply of several data sheet links per device (in the TARGET 3001! library browser)

Based on component specific needs

- Documentation of the surface properties of the component leads (in the TARGET 3001! component properties)

- Gathering advice regarding a suitable solder agens (in the TARGET 3001! component properties)

- Supporting varying simulation models because different surfaces cause different electrical behaviour (in the TARGET 3001!-Simulation)

- Documentation of the Temperature durability of a component, eg because of higher temperature (+30°) when leadfree soldering (in the TARGET 3001! component properties)

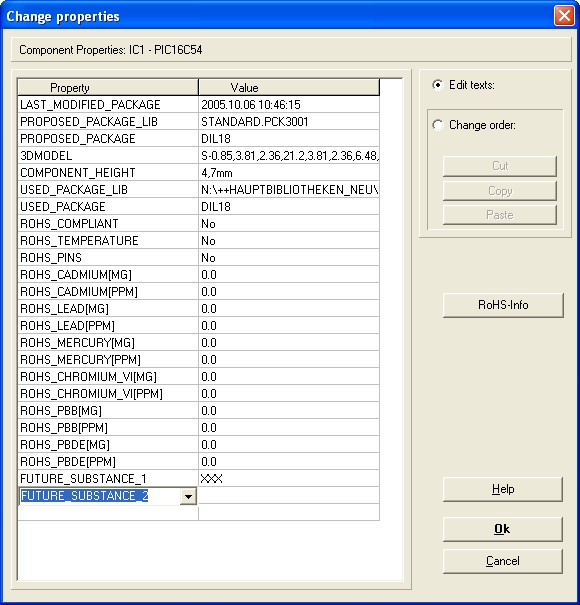

- Gathering distributors RoHS-information (in the TARGET 3001! component properties)

- Gathering quantities of those six substances mentioned in the RoHS-directive (in the TARGET 3001! component properties)

- Extensibility to more than six substances (in the TARGET 3001! component properties)

- Gathering different item/ordering numbers, eg RoHS compliant, not compliant (in the TARGET 3001! component properties)

- Mentioning of alternative device (in the TARGET 3001! component properties)

Based on layout specific needs

- expandability of soldering pads (longer design) to contribute to the needs of leadfree soldering (in the layout of the component package (footprints) or independently in every layout)

- larger spacings, to reduce risk of short-circuits (in menu "Check project")

- more space around any component for easier and more exact placement (in the TARGET 3001! autoplacer by giving additional grid-units distance to the next component)

Based on project specific needs

- Calculation of the hazardous amounts per project for assured documentation of the RoHS conformity of the whole project (in the TARGET 3001! BoM configuration and -analysis)

- Creation and and administration of variants of assembly within a project (in the TARGET 3001!-Variants)

The TARGET 3001! Component Management System (CMS) is flexible and expandable. It offers opportunity to adjustment to coming needs.

RoHS-compliance can individually be documented in the properties of any component: