MID Tutorial

Contents

- 1 Start the design on a 3D body

- 2 Place a component upon the surface of the 3D body

- 3 Turn a placed component by degrees

- 4 Move an already placed component

- 5 Component is elevated a bit

- 6 Calculate the air wires

- 7 Place tracks

- 8 Drag the corner of a track

- 9 Design Rule Check

- 10 STEP Format

- 11 Bill Of Material

- 12 Dispenser information

- 13 Order the project as a completely manufactured and assembled part

Start the design on a 3D body

Starting from a schematic in TARGET 3001! you now would like to place parts and tracks on a 3D body. Pressing the 3D button at this stage delivers an empty canvas because we first need to import a 3D construct. In menu "Actions" please use item "Prepare MID...". A browser opens to select a STEP file in Format *.stp which delivers the body to design on.

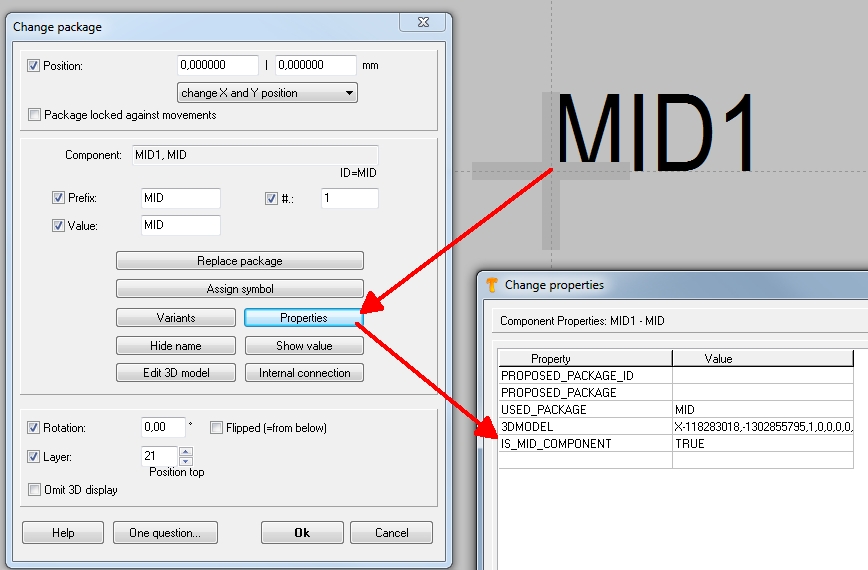

In the TARGET 3001! 2D layout view now a handle cross of a component will be placed which represents the 3D object to be seen in the 3D view. If you like to delete the imported 3D body you need to delete this handle cross in the 2D layout view. A double click on this handle cross demonstrates to us that the properties of that particular package shows the entry IS_MID_COMPONENT having the value TRUE.

Image: In the 2D Layoutview a special package is "prepared". This happens automatically. No need to do anything for the user.

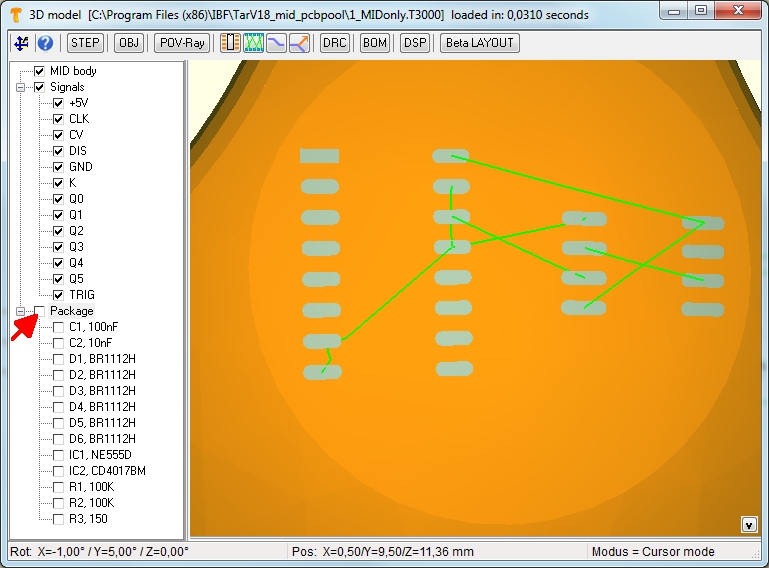

What we have here is a kind of plastic cap to which we'd like to apply some electronics according to our schematic.

To the left we see all signals as well as all component packages being determined by the schematic.

Image: The 3Dview shows a body to which the components and tracks shall be designed.

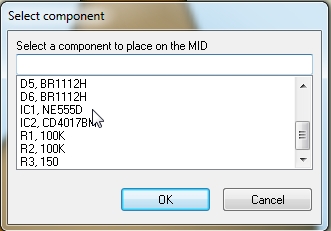

Place a component upon the surface of the 3D body

To place a component package to the body please use this button: ![]() The cursor image changes

The cursor image changes  and you move it to the spot where the center of a package shall be placed. A click makes a list pop up to select the desired package.

and you move it to the spot where the center of a package shall be placed. A click makes a list pop up to select the desired package.

In our case we select IC number one which is a NE555D timer.

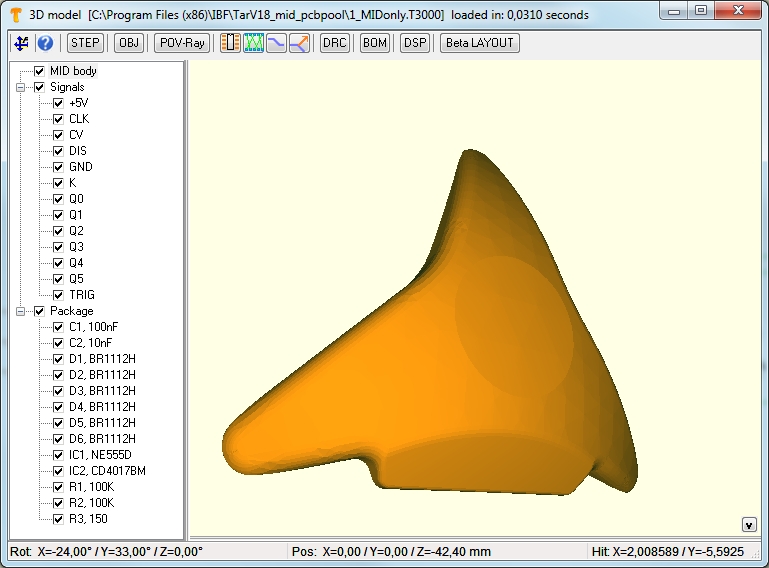

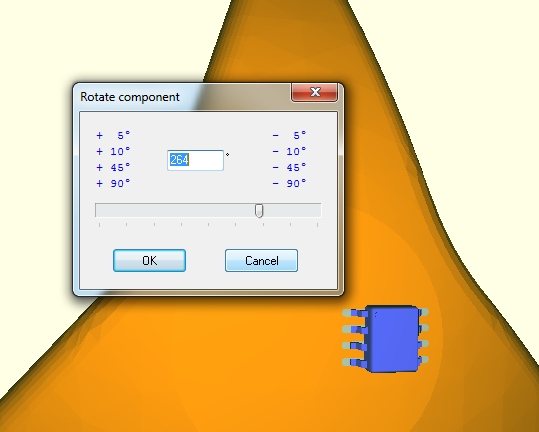

Turn a placed component by degrees

Immediately it gets placed and a further dialog allows rotation by degrees.

Image: Package placed, turn eventually.

Positive means counter clockwise, negative means clockwise. You also might enter degrees here individually

Now that we are still in the mode to place parts, we just hover to the next position. The same here. Fist click then select from the list. We select IC number two and place it. Again we have the opportunity to rotate the part. you can make this dialog pop up at a later time after having a part highlighted and pressing keyboar key [t] for turn.

Move an already placed component

Well, if the position might need a better placement so we highlight it by a click to its center, move the cursor to the desired spot and press keyboard key [d] for displacement. Immediately the package moves its center to the new spot, defined by the cursor tip. If the new place should not have the same inclination in space, you again maybe need to rotate it a bit.

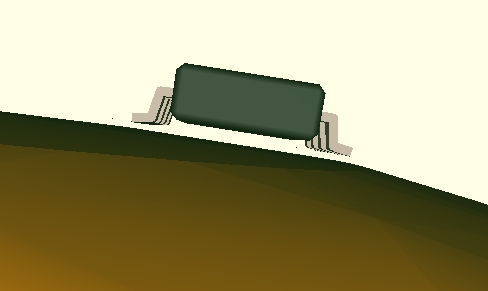

Component is elevated a bit

If it does not seem sufficient, do it again. If you rotate the body you will see that the tips of the leads are elevated a bit. These zero point two millimeters are OK and covered by the constructional process. It can be set in the Design Rule Check (DRC) dialog.

Image: Component elevated

Calculate the air wires

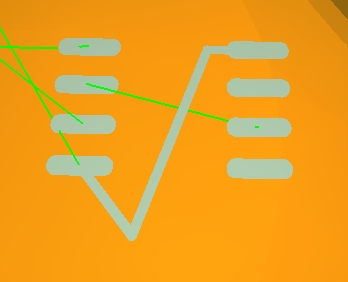

Use button: ![]() For these two parts we'd like to see the connections coming from the schematic. Creating the air wires gives information which connections now need to be routed. For a better view we fade out the packages for a moment -untick the box (arrow).

For these two parts we'd like to see the connections coming from the schematic. Creating the air wires gives information which connections now need to be routed. For a better view we fade out the packages for a moment -untick the box (arrow).

Image: Air wires calculated, the bodies of the two faded out

We look at the diagonal connection to the right we now would like to rout.

Place tracks

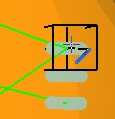

We use the button to place a track ![]() while instantly the cursor changes.

while instantly the cursor changes. ![]() If we come close to a pad a little snap on-box appears helping to meet the connection right.

If we come close to a pad a little snap on-box appears helping to meet the connection right.

Such a snap on box only appears at pads which have a signal being defined in the schematic. Pads with no signal don't show a snap on box.

Image: Snap on boxes in mode "Place tracks"

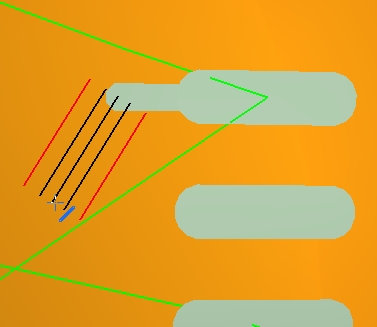

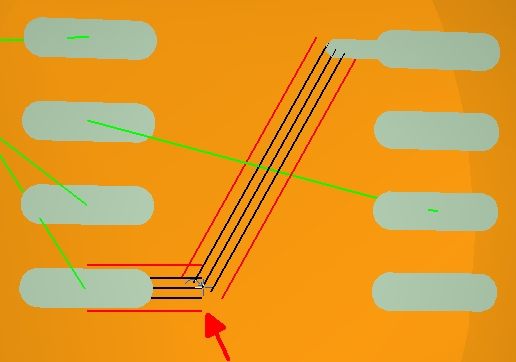

A click on the pad starts the track. The width of the track in black and its spacing in red are determined by the signal characteristics in the schematic.

Image: Snap on boxes in mode "Place tracks"

With every click a piece of track is placed. If you didn't manage to place the track neatly you can correct the route later. It is good to click often in order to create many little segments, easy to adapt lager to a smooth route. At least we arrive at the destination pad.

Image: Placed track, needs to be adapted a bit.

With [ESCAPE] you release the cursor from any mode and return to pointer mode.

Drag the corner of a track

Now we'd like to adapt this corner by dragging it into shape. Use the drag corner mode ![]() do a simple click to the corner while the image of the track segment changes. Now just move the mouse without key action

do a simple click to the corner while the image of the track segment changes. Now just move the mouse without key action

Bild: Enfachklick und lediglich die Maus bewegen.

If you have found the position just place it by a single click. You still can adapt the width of a track. Highlight it and press keyboard key [e] for edition.

We change the track width for example to zero point one millimeters. This will cause an error later when we start the design rule check.

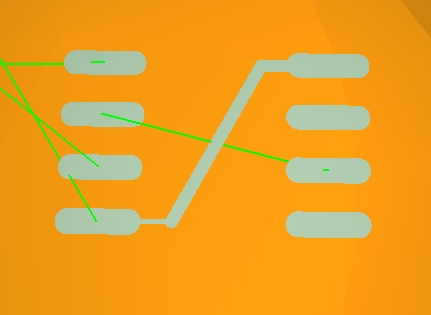

Image: Placed track. The air wire vanishes as soon as all airwires are calculated new (on button click.)

Also spacing violations: How to check them and how to correct them? So here we deliberately cause a spacing violation by placement of the track too close to a neighboured pad.

Image: The track above possibly will come too close to another, at the lower connection maybe the track is too thin...

Design Rule Check

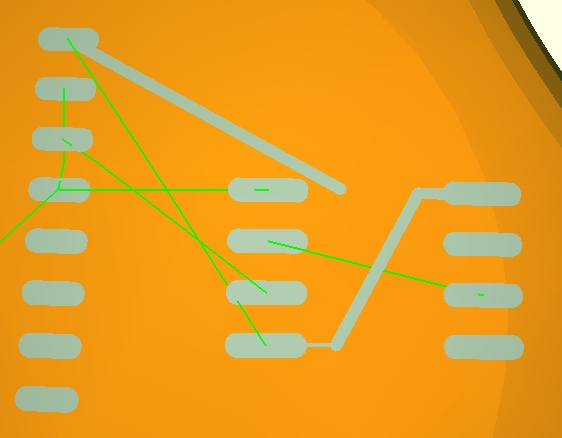

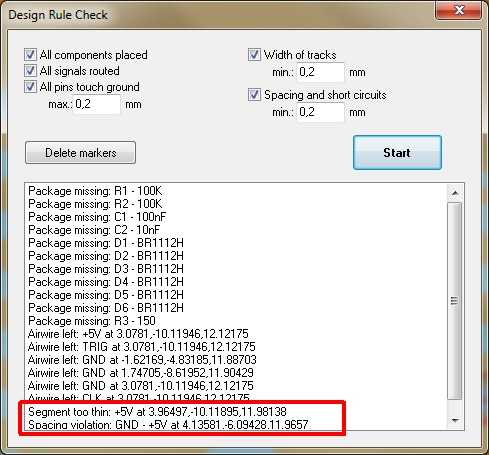

Now we start D R C the design rule check. It checks whether all components are placed, whether all signals are routed, all pins touch the ground with a certain tolerance given.

Also the width of tracks as well as spacings and schort circuits can be checked. When it is started it shows some packages missing as well as airwires left which is clear to us. But at the bottom of the list we see the hints "Segment too thin" and "Spacing violation" and this is what we have caused.

Image: The Design Rule Check in our example.

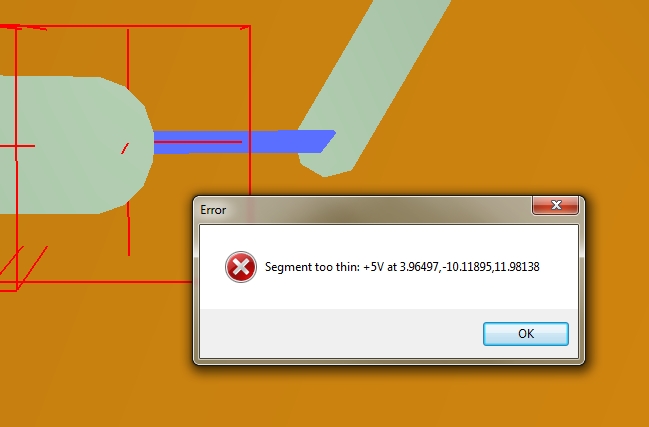

Every error is represented by a marker. Each one can be clicked to get information what it stands for. If clicked, the element in question is highlighted. Pressing keyboard key [e] allows to edit it. The same with the spacing violation. Since it has no corner to drag it is best to delete it and to draw it new.

Image: Click on a marker explains the error. Clicking OK highlights the element in order to edit it by [e].

Error markers can be deleted by the DRC dialog.

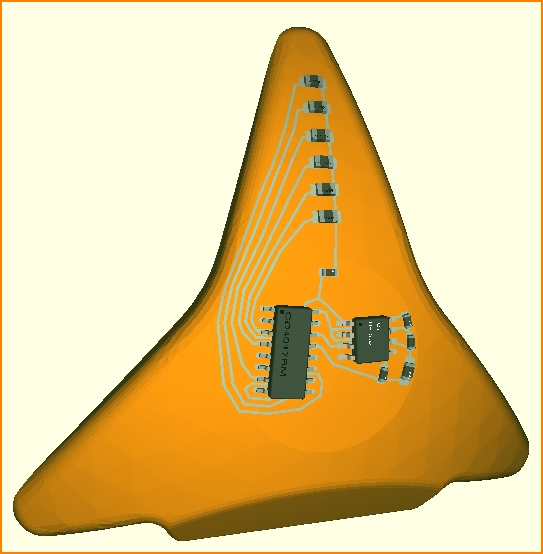

If all parts and tracks are properly placed, you may come to something like that. any part can be deleted at any time, any trach can be adapted at any time. You always have the schematic in the background. So any change of the electronic logic in the schematic can instantly find its consistent representation on your 3D construct.

Image: Layout, ready for manufacture (body as well as assembly).

STEP Format

To produce it you just would export all to a STEP file to hand it over to the manufacturer of your choice. Sure you can produce it yourself. The STEP format is industry standard.

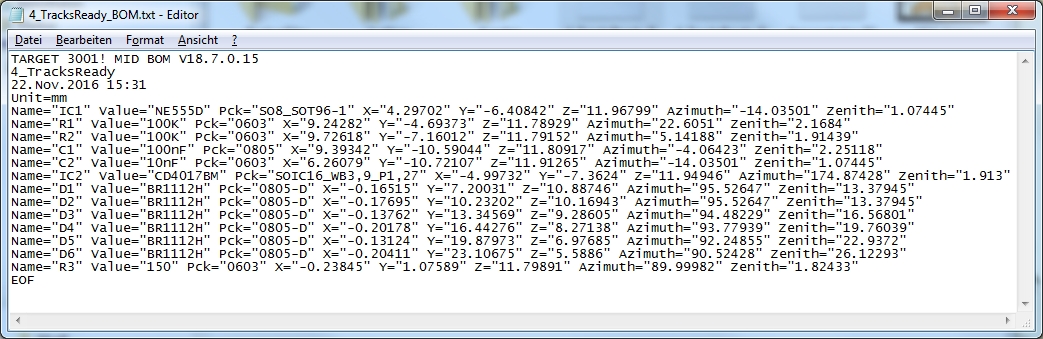

Bill Of Material

Regarding the assembly you first might want to have a lok at the Bill Of Material (BOM). It is a simple text file which can be read by any text editor giving any opportunity for formatting. All components in use are listed as well as their orientation angles including azimuth and zenit angles.

Image: The Bill of Material, BOM

All components are listet together with the angles of orientation including Azimut and Zenit.

Dispenser information

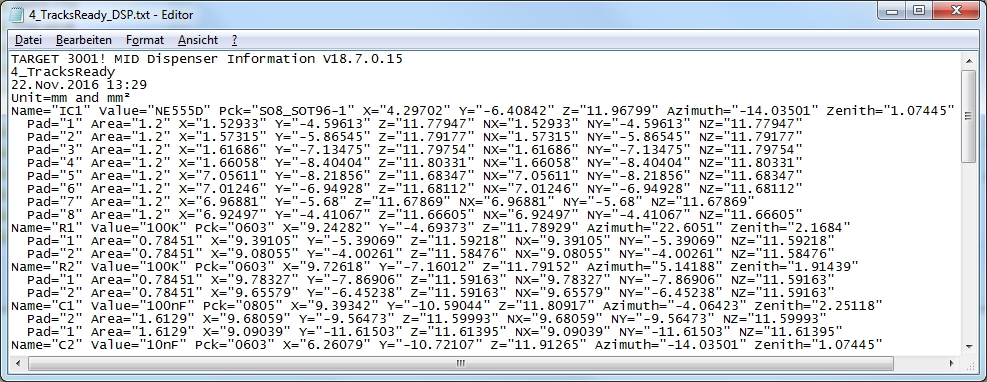

The same with dispenser information (Button DSP) in order to apply the solder agens to the pads. In addition to the name of the component all its pad coordinates are listed.

Image: Dispenser information as text file

Order the project as a completely manufactured and assembled part

If you want to order the completely produced and assembled part as a whole, just click the Beta LAYOUT TAB to request an offer from there. You only need to define the quantity, enter your personal data maybe give some additional instructions and press the "Request offer" button. An eMail is sent to Beta LAYOUT having your file appended and you will have an answer soon.