Milling big drill holes: Difference between revisions

Created page with "Kleiner Schalter, große Arbeitsersparnis: Beim Isolationsfräsen kann man nun Befestigungsbohrungen am Ende mit dem Umriss fräsen lassen und muss nicht extra große Bohrer e..." |

No edit summary |

||

| (One intermediate revision by one other user not shown) | |||

| Line 1: | Line 1: | ||

Small switch, big work saving: When isolation milling, you can now have big mounting drillholes milled at the end with the outline and do not have to clamp extra large drill bits:<br><br> | |||

[[File:MillBigDrills_EN.png| | [[File:MillBigDrills_EN.png|Isolation dialog]]<br> | ||

( | (Image 1: Dialog "isolation milling")<br><br> | ||

The lower switch does exactly that: If the board outline is milled with radius compensation, you can have the holes that are larger than the outline milling bit created with exactly this tool and save a lot of time reclamping. | |||

[[de:Fräse große Bohrlöcher]][[fr:Fraiser de grands trous de forage]] | [[de:Fräse große Bohrlöcher]][[fr:Fraiser de grands trous de forage]] | ||

Latest revision as of 09:59, 24 November 2021

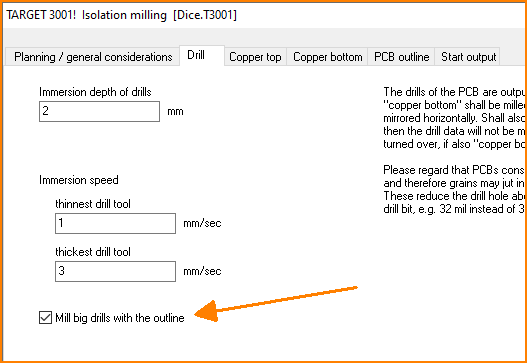

Small switch, big work saving: When isolation milling, you can now have big mounting drillholes milled at the end with the outline and do not have to clamp extra large drill bits:

(Image 1: Dialog "isolation milling")

The lower switch does exactly that: If the board outline is milled with radius compensation, you can have the holes that are larger than the outline milling bit created with exactly this tool and save a lot of time reclamping.