Assembly Service

The permanently decreasing size of SMT parts leads to a real challenge when it comes to soldering. DIY soldering in narrow layouts is nearly impossible. Why not use the unique service of TARGET 3001! and PCB-POOL(R) and let your prototype professionally be assembled? Calculate the cost in TARGET 3001! and give advice, where the parts should be bought. Order the assembly directly from TARGET 3001!. The assembly will be done at PCB-POOL(R).

Only a few steps are needed.

|}

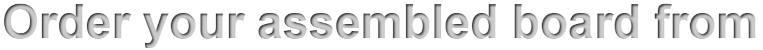

Image 1: Your schematic is finished, e.g. a step motor control

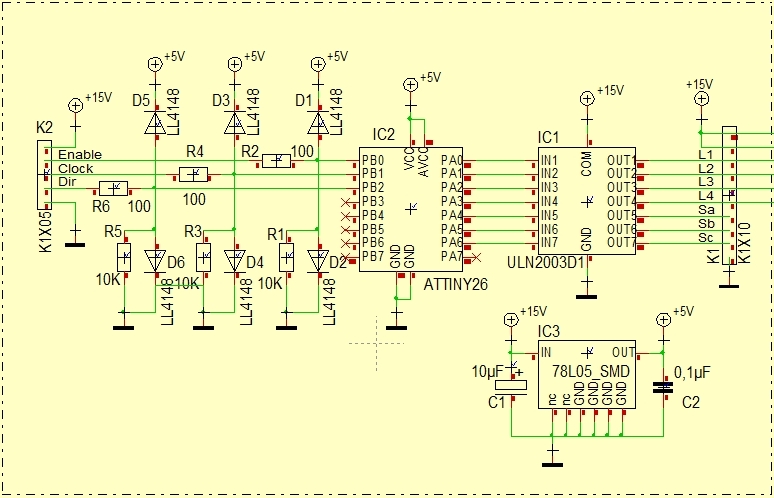

Image 2: Your double sided layout is finished

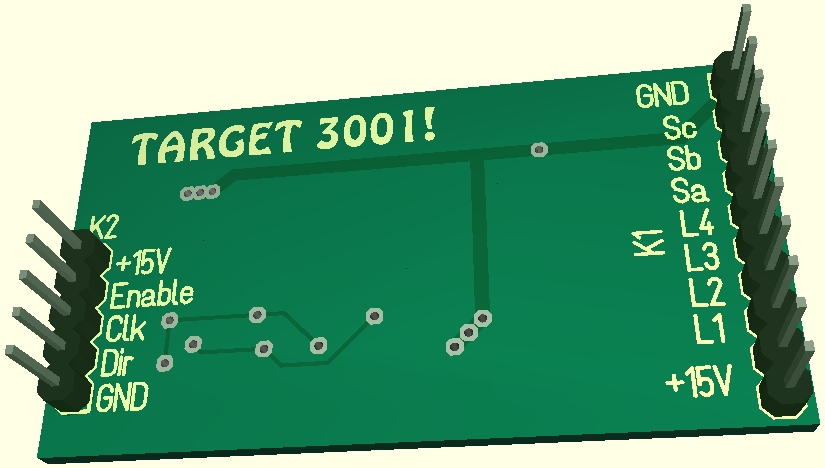

Image 3: Inspect the top side by the TARGET 3001! 3D view...

Image 4: ... or the soldering side. SMD-parts in TARGET 3001! get mounted by default on the bottom side. At any time you can change this.

Image 5: In menu "File" select entry "Produce PCB in PCB-POOL(R)".

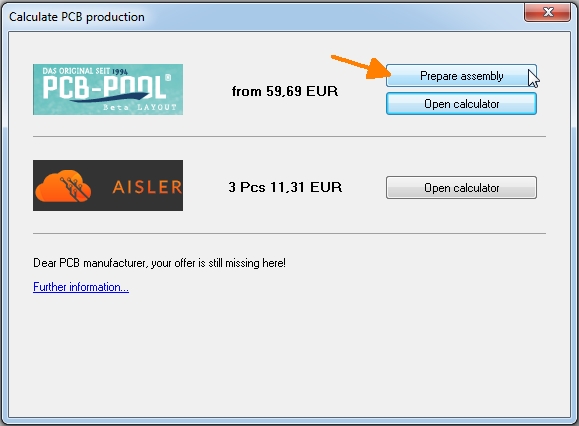

Image 6: Please opt for "Prepare assembly".

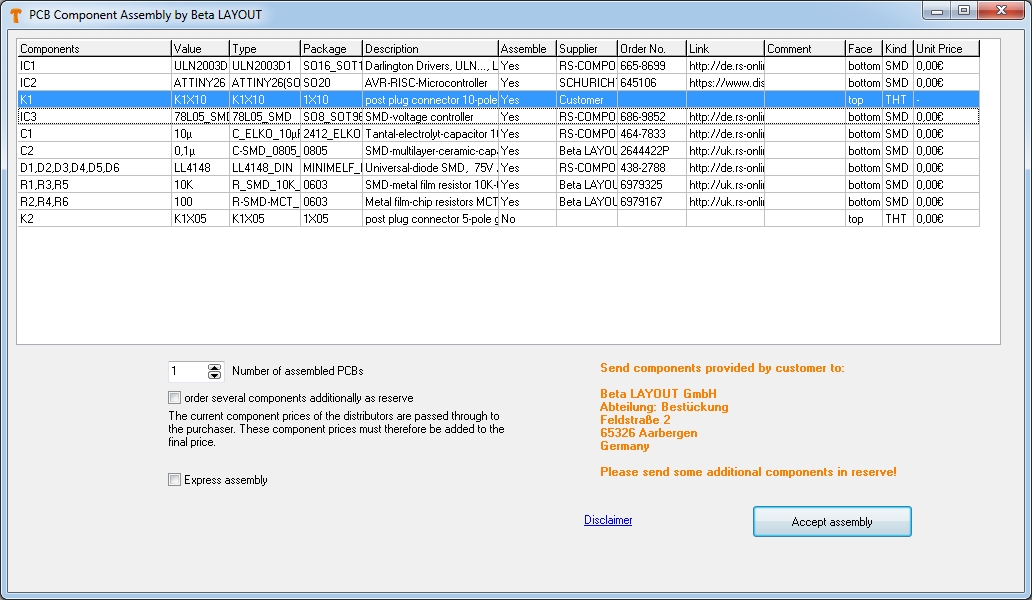

Image 7: The Bill of Material (BoM) opens. The column "Supplier" shows which source will be used by PCB-POOL(R). Some standard components are on stock at PCB-POOL=Beta LAYOUT (=option "Beta LAYOUT"). This saves time as well as freight charges.

Special: How to add an individual ordering number to a component of the BoM?

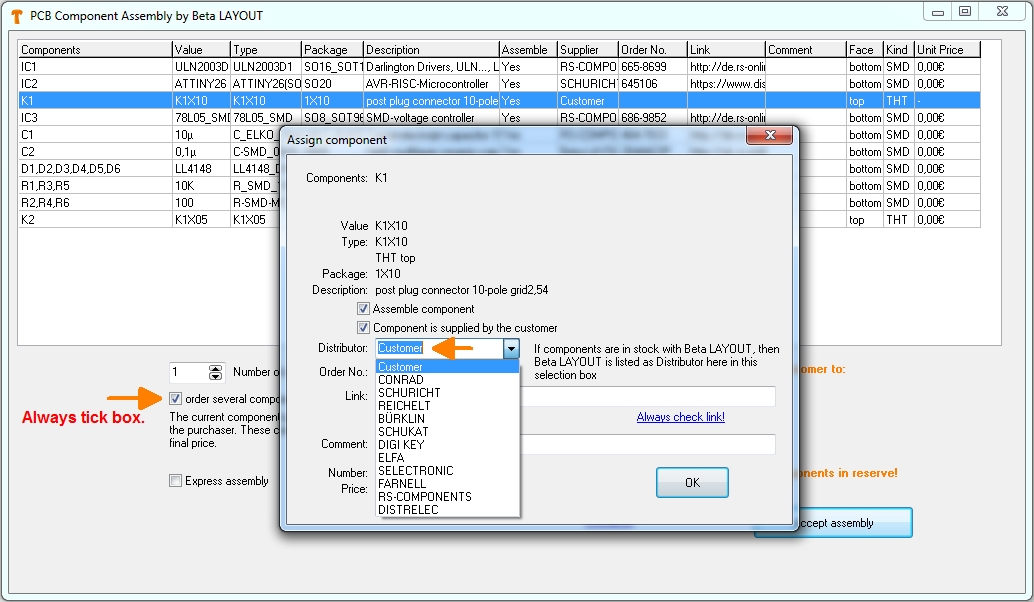

Image 8: Alternatively a component can be provided by the customer himself (=option "Customer"). Double click on a line opens the configurator accordingly. Ship the parts to the address given in orange font (covered by the dialog). Click "Accept assembly".

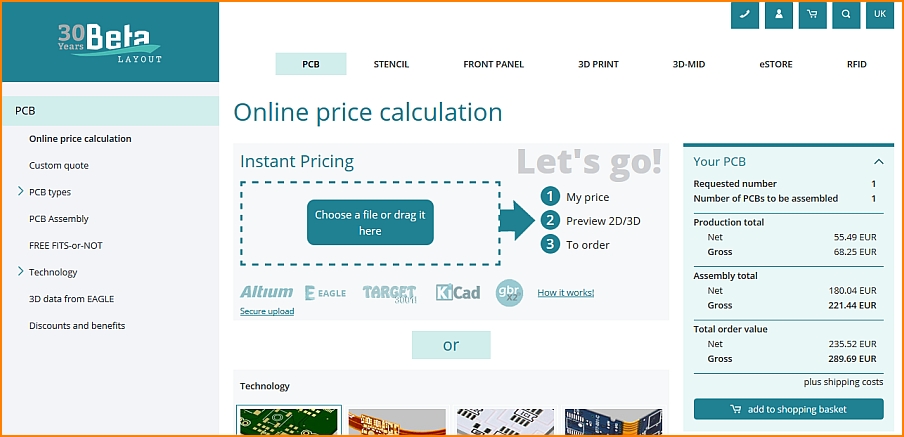

Image 9: The PCB-POOL(R) calculator shows the cost of PCB production and assembly as well.

Image 10: Gather data once more and submit.

That's all.

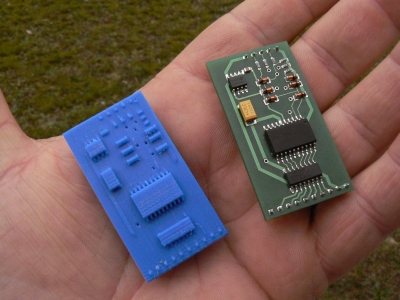

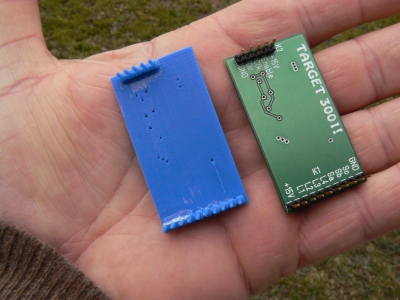

Image 11: In a few days you'll have them on your desk...

Assembled board and plastc dummy of the same How this?